Name: 12000BPH Linear Hot Melt OPP Labeling Machine 1 SET

Country: Yemen

Industry: Beverage

Details: This factory specializes in juice, drink water products, our opp labeling machine mainly label for plastic water bottle.

Name: 18000BPH OPP Hot Melt Glue Labeling Machine 1 SET

Country: India

Industry: Beverage

Details: This factory specializes in pure water and juice, mainly label for plastic bottle.

Name: 15000BPH Water Bottle Hot Melt Labeling Machine 1 SET

Country: Saudi Arabia

Industry: Beverage

Details: This factory specializes in bottle minearal water, our bopp labeling machine label for 500ml and 330ml plastic round bottle.

Name: 10000BPH Hot Melt BOPP Labeling Machine 1 SET

Country: Nicaragua

Industry: Beverage

Details: This factory specializes in pure water, our hot melt bopp labeling machine mainly label middle part for 300ml,600ml,1500ml bottle.

Name: 18000BPH Hot Melt BOPP Labeling Machine 1 SET

Country: Kenya

Industry: chemical and cosmetic industry

Details: This factory process for unilever company. this linear hot melt opp labeling machine label for 500ml plastic round bottle which filled in cleaner.

Touch Screen, LCD touch screen design and intelligent operating system(PLC control) will make sure machine feedback quick and accurate.

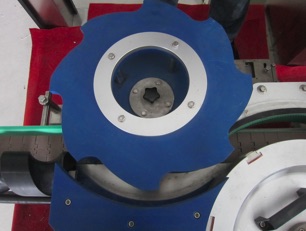

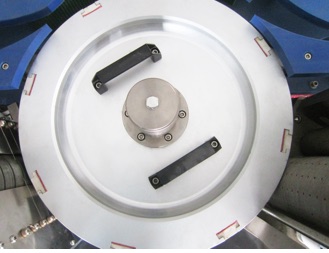

Bottle feeding wheel adopt ultra-high molecular materials processing,durable for positioning the bottle to make sure bottle goes into accurate labeling station.

Labeling rotating drum use high grade material produced by CNC, cut label adsorbed on it for sticking glue,and then paste label on bottle.

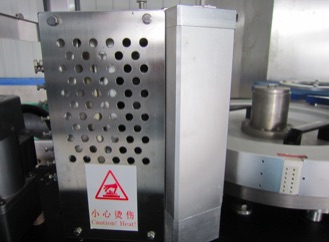

Coating system cut label rolling glue here.

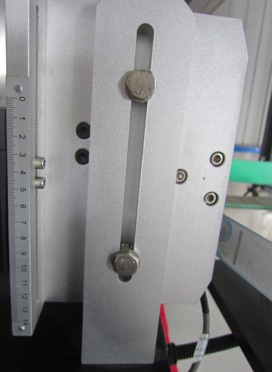

Position memory ruler: each place need to adjust beacuse of different size bottle. ruler will make sure operator can adjust machine easy to best place in short time

1. It applies to a row of paste volume, the use of local means glue, glue consumption of small, low running costs.

2,Due to the design of high-precision processing requirements of strict and meticulous assembly, so that the stability of the machine running, and production capacity can reach 10,000 bottles / hour.

3. Marked station is the heart of the aircraft, designed to complete the standard trademarks station transmission constant tension; trademarks automatic correction; labeling speed (revolution speed of the machine and the speed of rotation of the synthetic bottle speed) internal matching; not send bottles marked function; glue function is not scale-free; bottle labeling before and after the replacement of the normal type;

4. The host used on home cam design to replace the bottle-type simple; nose tight card using pneumatic means to increase the convenience of the host.

5. The overall automation and control the use of PLC control, the servo system, the inverter system, temperature control systems and other needs with comprehensive control of the point.

6. Overload protection, security, protection of the design of complete, multi-point and fault protection device to ensure that the alarm sound and light man-machine safety.

7. Centralized lubrication system allows the operation of machinery lubrication components more simple, more normal, more to ensure that the machine life. The machine is simple and convenient maintenance.

8. A specially designed folder structure to ensure that trademarks are trademarks of trademarks has always been flexible in compacting the folder block.

9. Servo motor-driven traction trademark agencies, Photoelectric color code detection and compensation structure of a trademark can be cut off to ensure that trademarks are timely, accurate, and neatly cut.

10. Biaxial screw propeller institutions bottle into the bottle so that a more stable, high-speed into the bottle so much more smoothly.

11. Inflatable bottle of the local function is the quality of the container (grams) low, allowing users to reduce operating costs.

12. Double disk structure to ensure that the user feed the least time to replace the membrane, so that the effective production of longer, more productive machines.

13. Specifically the constant tension of the membrane material detection and feedback control system ensures that the general membrane materials to achieve high quality labeling.