Name: Wrap Around Case Packer GB-D30 1 SET

Country: India

Industry: Medical

Details: This factory specializes in medical products, our wrap around case packer mainly wrap tray for god oil bottle

Name: Wrap Around Case Packer GB-30 1 SET

Country: Thailand

Industry: Beverage

Details: This factory specializes in energy drink, beverage juice, water, etc. our wrap around carton packer is for red bull energy drink can.

Name: Wrap Around Case Packer GB-20 1 SET

Country: Thailand

Industry: Beverage

Details: This factory specializes in beverage juice, water, etc. our wrap around carton packer is for PET Bottle(320ml 450ml), arrangement is 4*6

Name: Wrap Around Case Packer GB-20 1 SET

Country: Australia

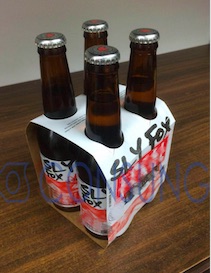

Industry: fresh glass bottled beer,canned beer etcs

Details: Our Wrap Around Case Packer is for beer bottle packaging, glass bottle is 330ml, before our carton packer, they will wrap 4 or 6bottle per wrap, then go to our wrap around case packer to pack 4bottle/wrap*6 and 6bottle/wrap*4

Carton-saving device of wrap around case packer is composed by step motor,network chain,stopper,etc. It can save more than 800 pieces of carton and provide carton for carton-suction device

Carton-suction device of wrap around carton packer is composed by servo motor,transmission chain,magnetic valve,sucker,etc and will be installed below bottle-dividing device. The function is to absorb equal quantity carton according to bottle-dividing group.

Carton-putting device of case packer is to form carton and will be installed below bottle-dividing device.

Bottle-pushing device of wrap around case packer is to convey regular arranged bottle to packing position

Carton-forming device of wrap around case packer mainly work with fixed slide and make carton forming in motion, and glue use photodetector to check carton and make feedback to PCC PCC control solenoid valve to achieve to make glue to top,front and back of carton

GB series includes automatic machines for the packaging of pvc bottle, pet bottle,glass bottle,paper and box in corrugated cardboard cases and/or trays without film which widely used in food,toy,chemical,cosmetic,medical and plastic industries. Wrap around case packers can achieve an output up to 35 packs per minute, according to the product. The packing arrangement can vary according to the containers shape and dimensions; in general, the most requested arrangement are: 2x3, 3x4 and 4x6.

Beer glass bottle wrap around case packer machine makes full wrap around carton packing for beer bottle.

Can wrap around case packer can make semi-tray packing for can .

1.Man-machine interface screen control.

2.Automatic error message display provides convenient shooting trouble.

3.It adopts detecting switch and muturly connected device, which can detect and adjust the operationg condition automatically during the whole prodction line.

4.It can operate with fully wrap around carton packing and tray packing.

5.Parameters can be set and modified on touch screen.

6.Scale provided for machine adjustment permits recording and convenience for adjustment.

Roller conveyor is widely used in assemble or transport line,physical distribution,container stuffing,etc. It is designed especially to convey flat-bottom items like cartons. Its all-steel structure makes sure that it holds its integrity when extended or curved. It helps to increase work efficiency,decrease labor intensity and reduce cost as well. The conveyor greatly facilitates material handling work for modern production.